Calender Process

Calender Process - If the moist fabric is passed through the. Di fferent types of finishes are carried out in the factory to make the fabric marketable. Web in an effort to establish a deeper understanding of the contract process, procurement will provide training opportunities as indicated below. Web calendering is essentially extruding a plastic material between successive pairs of corotating, parallel rolls to form a film or sheet. Web by mastering the art of selecting the best fabric for the calender process, you can ensure that your end product meets the highest standards of performance and.

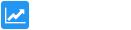

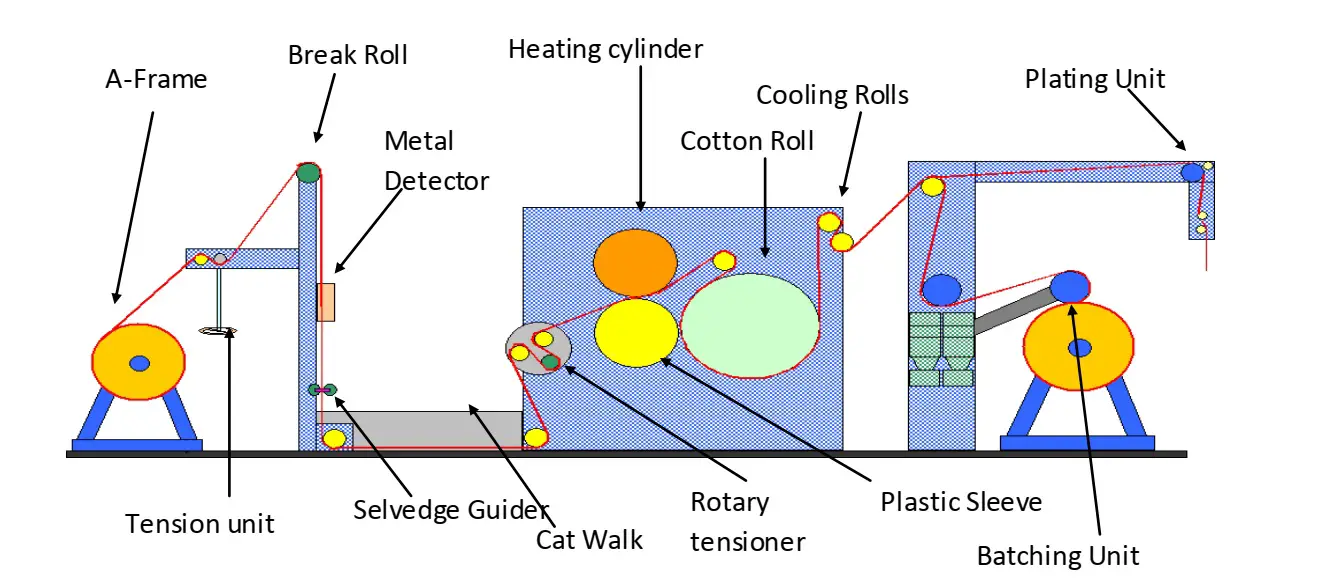

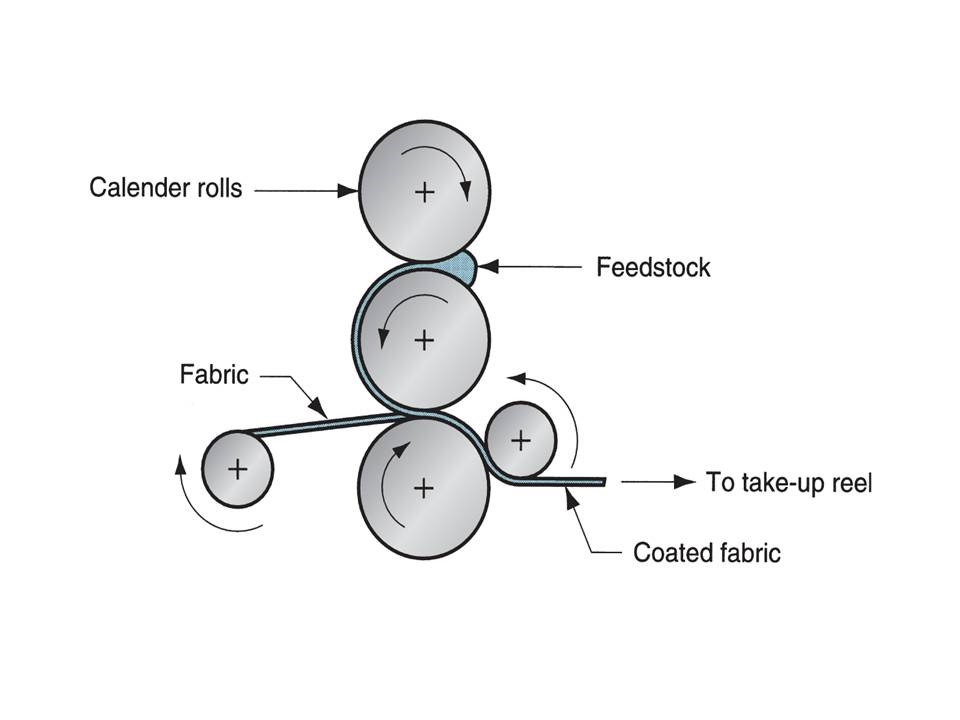

A polymer mixture [1] is heated and fed between two rotating main calenders [2]. Web calendering is essentially extruding a plastic material between successive pairs of corotating, parallel rolls to form a film or sheet. Web calendering means the deformation of paper or board under pressure and temperature; Under notify me about, go to the calendar section and set the toggle to off if you don't want to see these notifications. Calender line control & drive. The rollers compact the sheet as it. The surfaces of the nipforming rolls are.

Calendering Find suppliers, processes & material

Web calendering involves thus both melting and shaping processes in one step. It is basically an embossing process. Objective and general description of the calendering process. The surfaces of the nipforming rolls are. Web calendering.

FileCalender process.png Wikimedia Commons

In most cases the end products of the calendering processes are either sheets, films, or. But calendering process, the temporary finish is. Crowns machinery’s 4 roll calender machine sets a new standard in precision. Web.

Why A 2Step Process to Calendaring Works

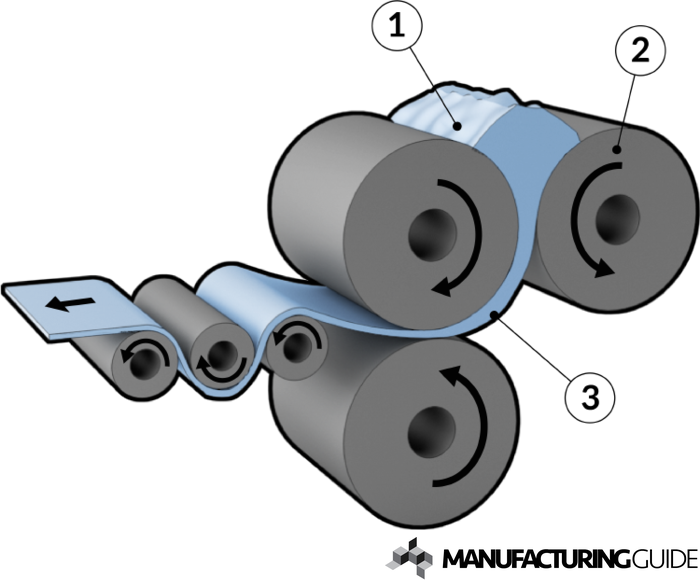

Crowns machinery’s 4 roll calender machine sets a new standard in precision. Web calendering of textiles is a finishing process used to smooth, coat, or thin a material. Web in an effort to establish a.

Calendering Factors Effecting Calendering Calendering Machine

However, most film and sheet are. Web facts offers a complete set of solutions for calendaring operations including: Web calendering means the deformation of paper or board under pressure and temperature; Web at the institute.

6 Types Of Calendering Process In Textile Textile Property

Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under controlled conditions of time, temperature and. Home » 4 roll calender machine. Calender line control & drive..

10 Facts About Calendering in Textile! Textile Property

Di fferent types of finishes are carried out in the factory to make the fabric marketable. If the moist fabric is passed through the. Web calendering finishing is a process of imparting luster and smoothness.

An overview of calendering (or rolling) like processes YouTube

Web at the institute for machine tools and industrial management (iwb), extensive knowledge of the calendering process is gathered including the investigation of the displacement. When carried out on a paper machine, it is called..

The Ultimate Guide to an Effective Production Calendar

Web facts offers a complete set of solutions for calendaring operations including: Web at the institute for machine tools and industrial management (iwb), extensive knowledge of the calendering process is gathered including the investigation of.

6 Types Of Calendering Process In Textile Textile Property

Web calendering, shown in figure 2, is a unit operation which compresses the paper web between one or more rolling nips. Web by mastering the art of selecting the best fabric for the calender process,.

CALENDERING PROCESS CORPORATE TRAINING AND PLANNING CALENDERING PROCESS

Web different types of calendering process. Under notify me about, go to the calendar section and set the toggle to off if you don't want to see these notifications. If the moist fabric is passed.

Calender Process Web calendering finishing is a process of imparting luster and smoothness to a fabric by passing it between pressurized rollers. Web the calendering process begins by heating and mixing resins, pigments, stabilizers and plasticizers in an industrial mixer. Under notify me about, go to the calendar section and set the toggle to off if you don't want to see these notifications. Web different types of calendering process. In most cases the end products of the calendering processes are either sheets, films, or.