Flow Meter Peak Accuracy

The concept of peak accuracy in flow meters is crucial for various industries, including oil and gas, water treatment, and chemical processing. Achieving peak accuracy in flow measurement is essential for ensuring the efficiency, safety, and profitability of operations. In this article, we will delve into the world of flow meters, exploring the factors that affect their accuracy, the different types of flow meters, and the techniques used to optimize their performance.

Understanding Flow Meter Accuracy

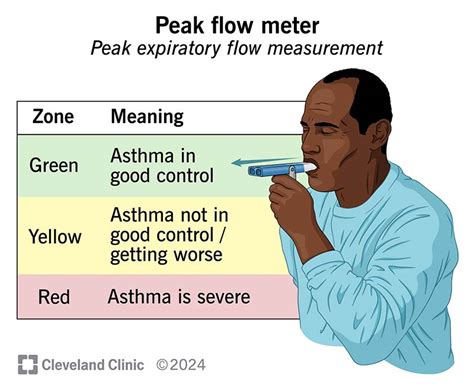

Flow meter accuracy refers to the degree of closeness of the measured flow rate to the actual flow rate. It is typically expressed as a percentage of the full-scale range or as a absolute value. The accuracy of a flow meter is influenced by several factors, including the type of flow meter, the fluid being measured, the flow rate, and the operating conditions. Peak accuracy, in particular, refers to the highest level of accuracy that a flow meter can achieve under optimal conditions.

Factors Affecting Flow Meter Accuracy

Several factors can affect the accuracy of a flow meter, including:

- Fluid Properties: The viscosity, density, and temperature of the fluid being measured can impact the accuracy of the flow meter. For example, high-viscosity fluids can cause the flow meter to under-register the flow rate, while low-viscosity fluids can cause it to over-register.

- Flow Rate: The flow rate of the fluid can also affect the accuracy of the flow meter. Flow meters are typically calibrated to operate within a specific flow rate range, and operating outside of this range can lead to decreased accuracy.

- Operating Conditions: The operating conditions, such as pressure, temperature, and vibration, can also impact the accuracy of the flow meter. For example, high temperatures can cause the flow meter to expand, leading to decreased accuracy.

- Installation: The installation of the flow meter can also affect its accuracy. Improper installation, such as incorrect piping or inadequate straight-run lengths, can lead to decreased accuracy.

Types of Flow Meters

There are several types of flow meters available, each with its own strengths and weaknesses. Some of the most common types of flow meters include:

- Differential Pressure Flow Meters: These flow meters measure the difference in pressure across a constriction in the pipe to calculate the flow rate.

- Velocity Flow Meters: These flow meters measure the velocity of the fluid to calculate the flow rate.

- Mass Flow Meters: These flow meters measure the mass of the fluid flowing through the pipe to calculate the flow rate.

- Ultrasonic Flow Meters: These flow meters use ultrasonic waves to measure the velocity of the fluid and calculate the flow rate.

- Coriolis Flow Meters: These flow meters use the Coriolis effect to measure the mass flow rate of the fluid.

Techniques for Optimizing Flow Meter Accuracy

To optimize the accuracy of a flow meter, several techniques can be employed, including:

- Calibration: Regular calibration of the flow meter can help ensure that it is operating within its specified accuracy range.

- Installation: Proper installation of the flow meter, including correct piping and adequate straight-run lengths, can help minimize errors.

- Maintenance: Regular maintenance of the flow meter, including cleaning and replacing worn or damaged parts, can help ensure optimal performance.

- Flow Conditioning: Flow conditioning devices, such as flow straighteners or flow conditioners, can help improve the accuracy of the flow meter by minimizing swirl and turbulence in the pipe.

- Data Analysis: Advanced data analysis techniques, such as machine learning algorithms, can be used to analyze flow meter data and identify trends and patterns that can help optimize accuracy.

Peak accuracy in flow meters is crucial for ensuring the efficiency, safety, and profitability of operations. By understanding the factors that affect flow meter accuracy and employing techniques to optimize performance, operators can minimize errors and maximize productivity.

Case Study: Optimizing Flow Meter Accuracy in a Chemical Processing Plant

A chemical processing plant was experiencing issues with inaccurate flow measurements, which were resulting in decreased productivity and increased costs. To address this issue, the plant implemented a flow meter calibration program, which included regular calibration of all flow meters and verification of their accuracy. The plant also installed flow conditioning devices to minimize swirl and turbulence in the pipe, and implemented advanced data analysis techniques to analyze flow meter data and identify trends and patterns.

As a result of these efforts, the plant was able to improve the accuracy of its flow meters, resulting in increased productivity and decreased costs. The plant also reduced its environmental impact by minimizing waste and optimizing resource usage.

Optimizing flow meter accuracy is critical for ensuring the efficiency, safety, and profitability of operations. By understanding the factors that affect flow meter accuracy and employing techniques to optimize performance, operators can minimize errors and maximize productivity.

Future Trends in Flow Meter Technology

The future of flow meter technology is likely to be shaped by advances in digitalization, automation, and artificial intelligence. Some of the trends that are expected to impact the flow meter industry include:

- Digitalization: The increasing use of digital technologies, such as cloud-based platforms and mobile apps, is expected to improve the accuracy and efficiency of flow meters.

- Automation: The use of automation technologies, such as machine learning algorithms and robotics, is expected to improve the accuracy and reliability of flow meters.

- Artificial Intelligence: The use of artificial intelligence technologies, such as predictive analytics and natural language processing, is expected to improve the accuracy and efficiency of flow meters.

Conclusion

Peak accuracy in flow meters is crucial for ensuring the efficiency, safety, and profitability of operations. By understanding the factors that affect flow meter accuracy and employing techniques to optimize performance, operators can minimize errors and maximize productivity. As the flow meter industry continues to evolve, it is likely that we will see advances in digitalization, automation, and artificial intelligence that will further improve the accuracy and efficiency of flow meters.

What is the importance of flow meter accuracy in industrial processes?

+Flow meter accuracy is crucial for ensuring the efficiency, safety, and profitability of industrial processes. Inaccurate flow measurements can result in decreased productivity, increased costs, and environmental hazards.

What are the common factors that affect flow meter accuracy?

+The common factors that affect flow meter accuracy include fluid properties, flow rate, operating conditions, and installation. These factors can impact the accuracy of the flow meter and must be considered when selecting and installing a flow meter.

How can flow meter accuracy be optimized?

+Flow meter accuracy can be optimized by calibrating the flow meter regularly, installing flow conditioning devices, and using advanced data analysis techniques. These techniques can help minimize errors and maximize productivity.