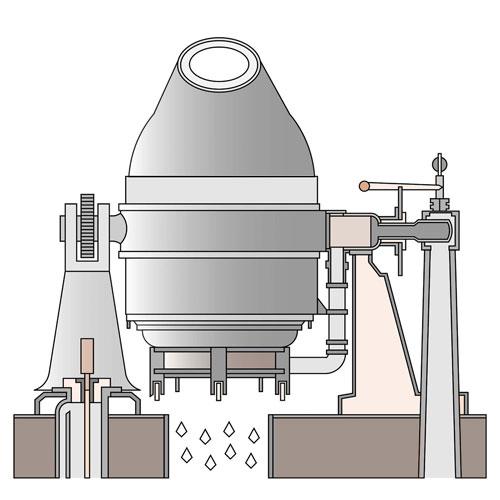

Bessemer Process Drawing

Bessemer Process Drawing - The bessemer process was the first method for making steel cheaply and in large quantities, developed during the early 1850s. Major advance in steelmaking occurred in 1855, when henry bessemer took out his first patent for the production of malleable iron and steel without using fuel. The process is named after its inventor, henry bessemer, who took out a patent on the process in 1855. The bessemer converters are introduced into all. Web steel was still unproven as a structural metal and production was slow and costly.

Modern steel is made using technology based on bessemer's process. Web the bessemer process, was the first inexpensive process for the mass production of steel from molten pig iron, before the development of the open hearth furn. Bessemer was knighted in 1879 for his contribution to science. Web steel was still unproven as a structural metal and production was slow and costly. The bessemer converters are introduced. Web 32k views 7 years ago. Web the bessemer process was the first inexpensive industrial process for the mass production of steel from molten pig iron before the development of the open hearth furnace.

Bessemer process

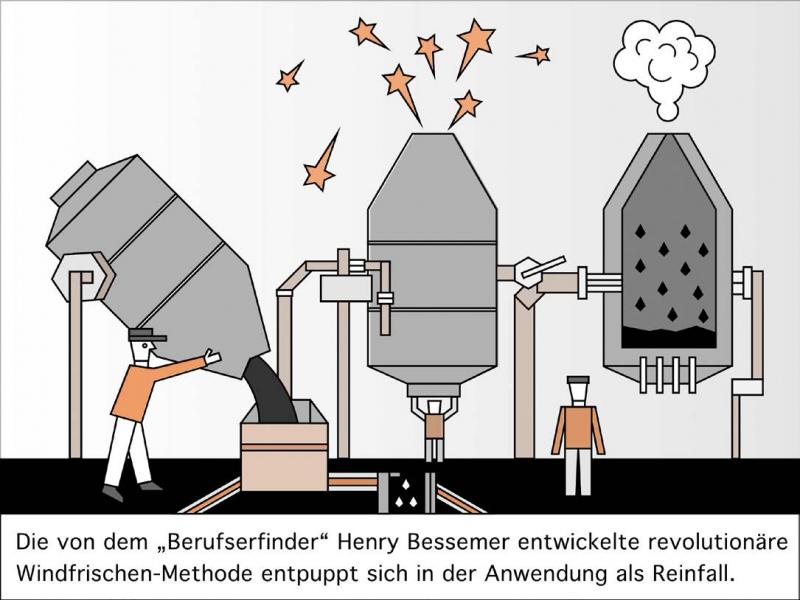

The cooperation between science and technology proves to be a great success. Major advance in steelmaking occurred in 1855, when henry bessemer took out his first patent for the production of malleable iron and steel.

Engraving depicting the Bessemer process for the mass production of

What it is and how it changed history while you may not know what the bessemer process is, every single person has benefited from its invention and discovery. Web the bessemer process was the first.

Steel Making Bessemer Process HighRes Vector Graphic Getty Images

The process is named after its inventor, henry bessemer, who took out a patent on the process in 1855. Web the bessemer process was the first cheap and easy way to make steel. Bessemer realized.

Bessemer Converter Schematic Diagram Bessemer Process Was The First

The basic principle behind the process is the removal of impurities and the controlled oxidation of elements present in the molten iron to achieve the desired composition and properties of steel. What it is and.

The Bessemer Process Drawing by Print Collector Fine Art America

Web the bessemer process is a steelmaking technique invented during the industrial age. That was until 1856 when henry bessemer came up with a more effective way to introduce oxygen into molten iron to reduce.

115. The Bessemer Process

It was named after the british inventor sir henry bessemer, who worked to develop the process in the 1850s. The basic principle behind the process is the removal of impurities and the controlled oxidation of.

The Bessemer Steel Process

Web 1 acid bessemer process. Web steel was still unproven as a structural metal and production was slow and costly. The key principle is removal of impurities from the iron by oxidation with air being.

The Bessemer Process Environment & Society Portal

Web october 21, 2021 the bessemer process: The bessemer process helped expand the steel industry in the 1800s by making the process more efficient. The key principle is removal of impurities from the iron by.

Steel Making Bessemer Process stock illustration Getty Images

The process is named after its inventor, henry bessemer, who took out a patent on the process in 1855. Major advance in steelmaking occurred in 1855, when henry bessemer took out his first patent for.

The Bessemer Process Environment & Society Portal

The bessemer converters are introduced. Web 1 acid bessemer process. Bessemer realized that the subsequent oxidation of the silicon and carbon in the iron would release heat and that, if a large enough vessel were.

Bessemer Process Drawing The key principle is removal of impurities from the iron by oxidation with air being blown through the molten iron. The basic principle behind the process is the removal of impurities and the controlled oxidation of elements present in the molten iron to achieve the desired composition and properties of steel. Web the bessemer process, was the first inexpensive process for the mass production of steel from molten pig iron, before the development of the open hearth furn. The bessemer converters are introduced into all. Web bessemer process is a converter steelmaking technology in which air is blown into molten iron from the bottom of a converter with an acidic lining, and an exothermic chemical reaction occurs when the molten iron.

/Bessemer-process01-3000-3x2gty-58b4e7c75f9b586046963aff.jpg)