Deep Draw Forming

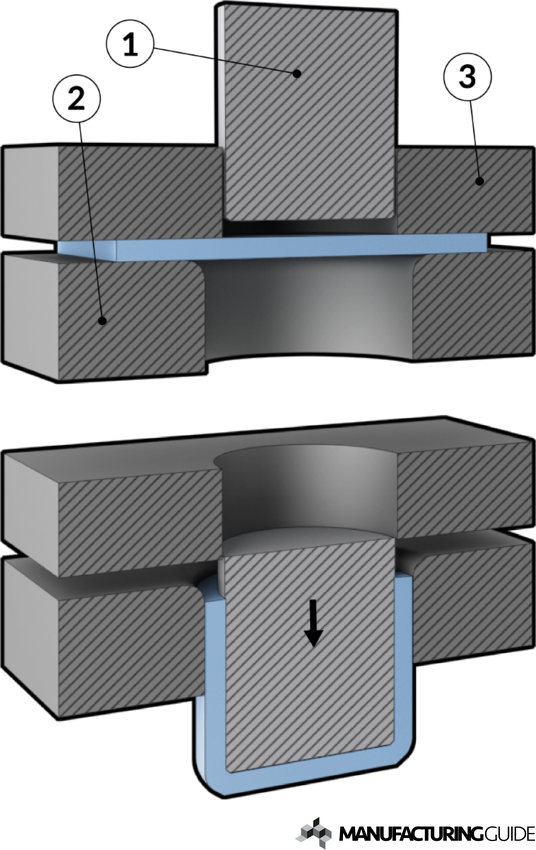

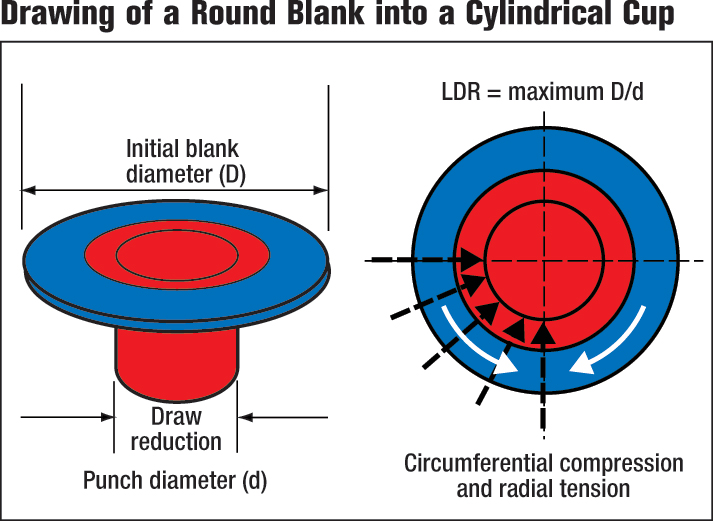

Deep Draw Forming - Because thicker materials are stiffer, they hold together better during deep drawing. Web deep drawing explained: Deep drawing is a sheet metal forming process by which a sheet metal blank is slightly clamped along its perimeter by a blank holder and radially drawn into a forming die by use of a punch. The deep draw forming process begins with metal blanks. 3] if the ratio of height to diameter of the product is greater than 0.5 then this drawing operation is known as deep drawing.

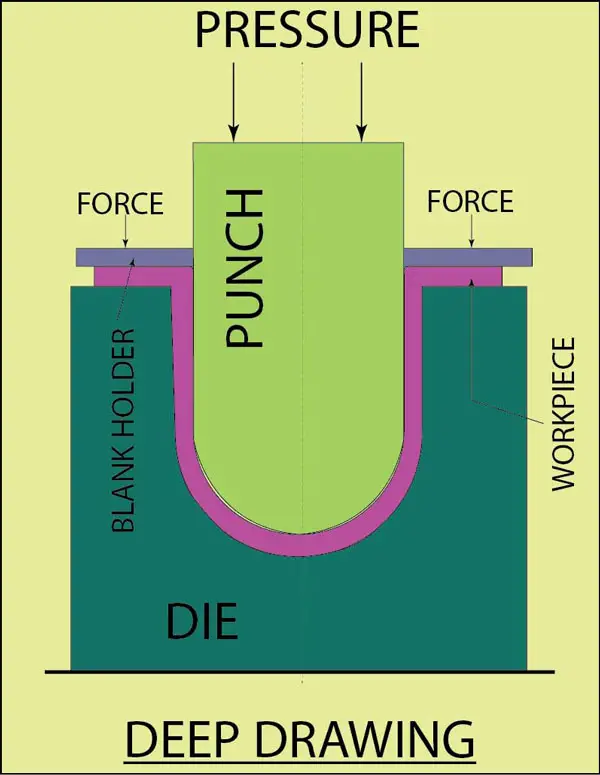

The deep draw forming process begins with metal blanks. Benefits and industrial applications deep drawing process. Because thicker materials are stiffer, they hold together better during deep drawing. Web 1] deep drawing is the process of converting blank of sheet metal into a cylindrical containers with a flat or hemispherical base. Blankholder restraining force controls radial material flow into the die cavity. Deep drawing is a sheet metal forming process by which a sheet metal blank is slightly clamped along its perimeter by a blank holder and radially drawn into a forming die by use of a punch. Other important factors for successful deep drawing are the size, accuracy, and.

best deep drawing process, by chris YouTube

Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Deep drawing is especially beneficial when producing.

Deep draw plastic vacuum forming YouTube

Key design principles & tips for successful draws key elements in deep drawing. Blankholder restraining force controls radial material flow into the die cavity. A round or shaped portion of metal is cut from the.

Deep drawing Find suppliers, processes & material

The deep draw forming process begins with metal blanks. The basics deep drawing produces a part from a flat blank via the action of a punch force onto the blank. Web these other forming methods.

Deep Drawing from A to Z MetalForming Magazine Article

The basics deep drawing produces a part from a flat blank via the action of a punch force onto the blank. Typical end products include hollow cylindrical or rectangular components with straight, curved, or tapered.

The Deep Draw Hydroforming Process & Advantages American Hydroformers

Because thicker materials are stiffer, they hold together better during deep drawing. Typical end products include hollow cylindrical or rectangular components with straight, curved, or tapered sides. Web deep drawing is a metal forming process.

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

2] it is combination of metal forming process & sheet metal process. Other important factors for successful deep drawing are the size, accuracy, and. In the bulging process a. Deep drawing is a sheet metal.

Our Specialty is Deep Draw Forming — Engel Diversified Industries

3] if the ratio of height to diameter of the product is greater than 0.5 then this drawing operation is known as deep drawing. Web deep drawing is a metal forming process for creating seamless,.

Deep Drawing from A to Z MetalForming Magazine Article

Benefits and industrial applications deep drawing process. Web mhdd is a kind of sheet hydroforming method in which a counterpressure is applied to enhance material flow and achieve uniform deformation with the control of thickening.

Deep Draw Process Precision Manufacturing Capabilities by PMP

A round or shaped portion of metal is cut from the drawn part. Deep drawing is especially beneficial when producing high volumes, since unit cost decreases. 3] if the ratio of height to diameter of.

The Last Guide to Sheet Metal Forming You Will Ever Need (2022)

Typical end products include hollow cylindrical or rectangular components with straight, curved, or tapered sides. That force pulls (draws) the blank into a die cavity, causing the flange to compress circumferentially. Web mhdd is a.

Deep Draw Forming Web bending and forming drawing can be defined as a forming process in which the flow of metal into a cavity or over a post is controlled. 3] if the ratio of height to diameter of the product is greater than 0.5 then this drawing operation is known as deep drawing. The basics deep drawing produces a part from a flat blank via the action of a punch force onto the blank. Key design principles & tips for successful draws key elements in deep drawing. Other important factors for successful deep drawing are the size, accuracy, and.