Metal Drawing Process

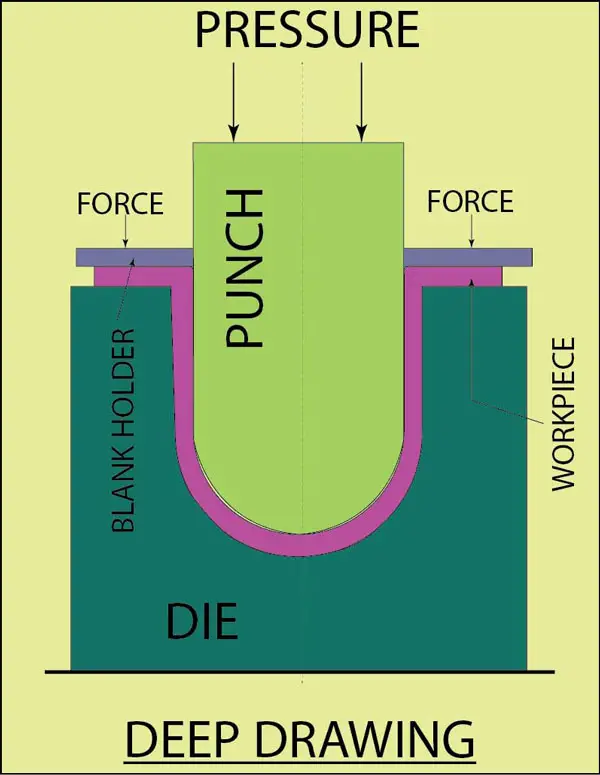

Metal Drawing Process - Types of deep drawing parts The surface of the bar or tube is coated with a drawing lubricant such as phosphate or oil to aid cold. Web screws, bonding, riveting, and welding are the most common ways to assemble in fab departments. Web one of the significant advantages of metal drawing is its ability to work with a wide range of metals. Web applications of metal drawing process metal drawing is utilised to produce wires used in electrical industries made from materials like copper and aluminium.

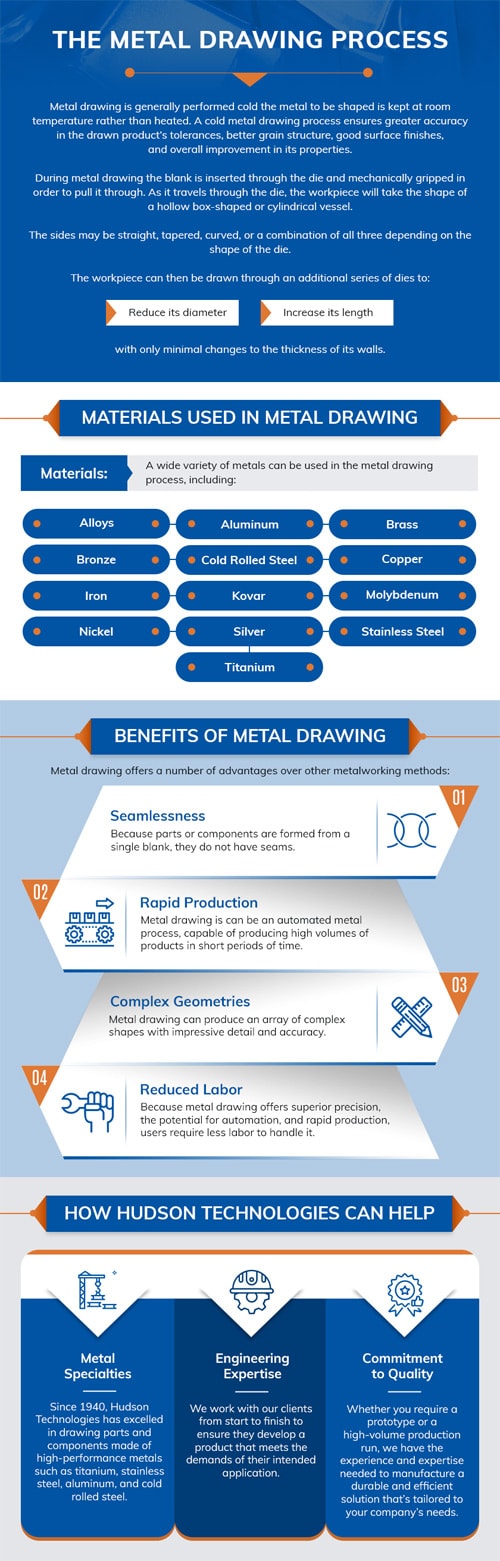

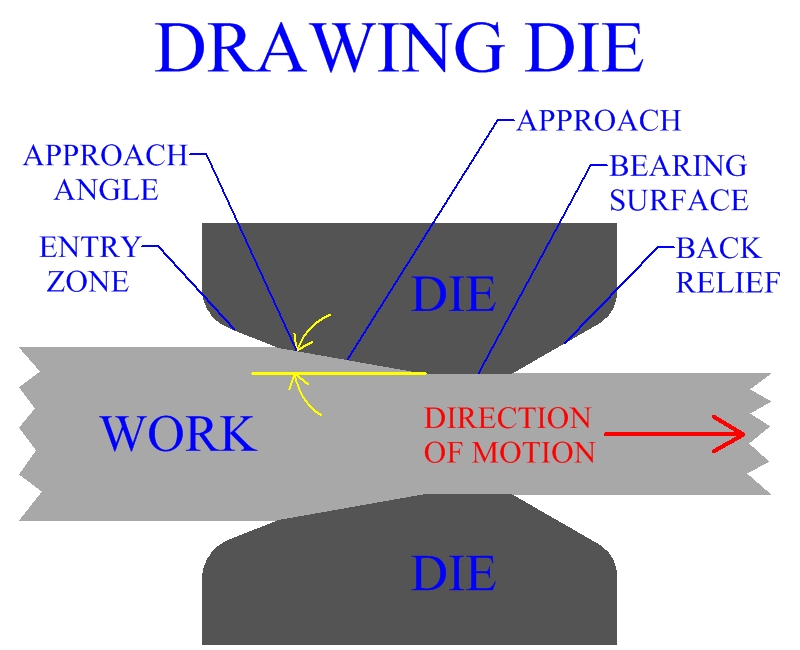

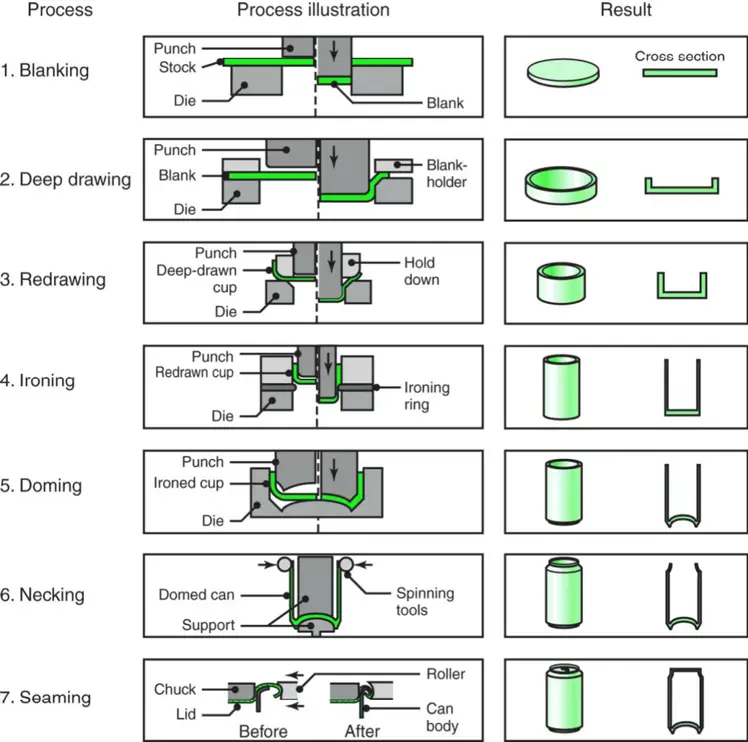

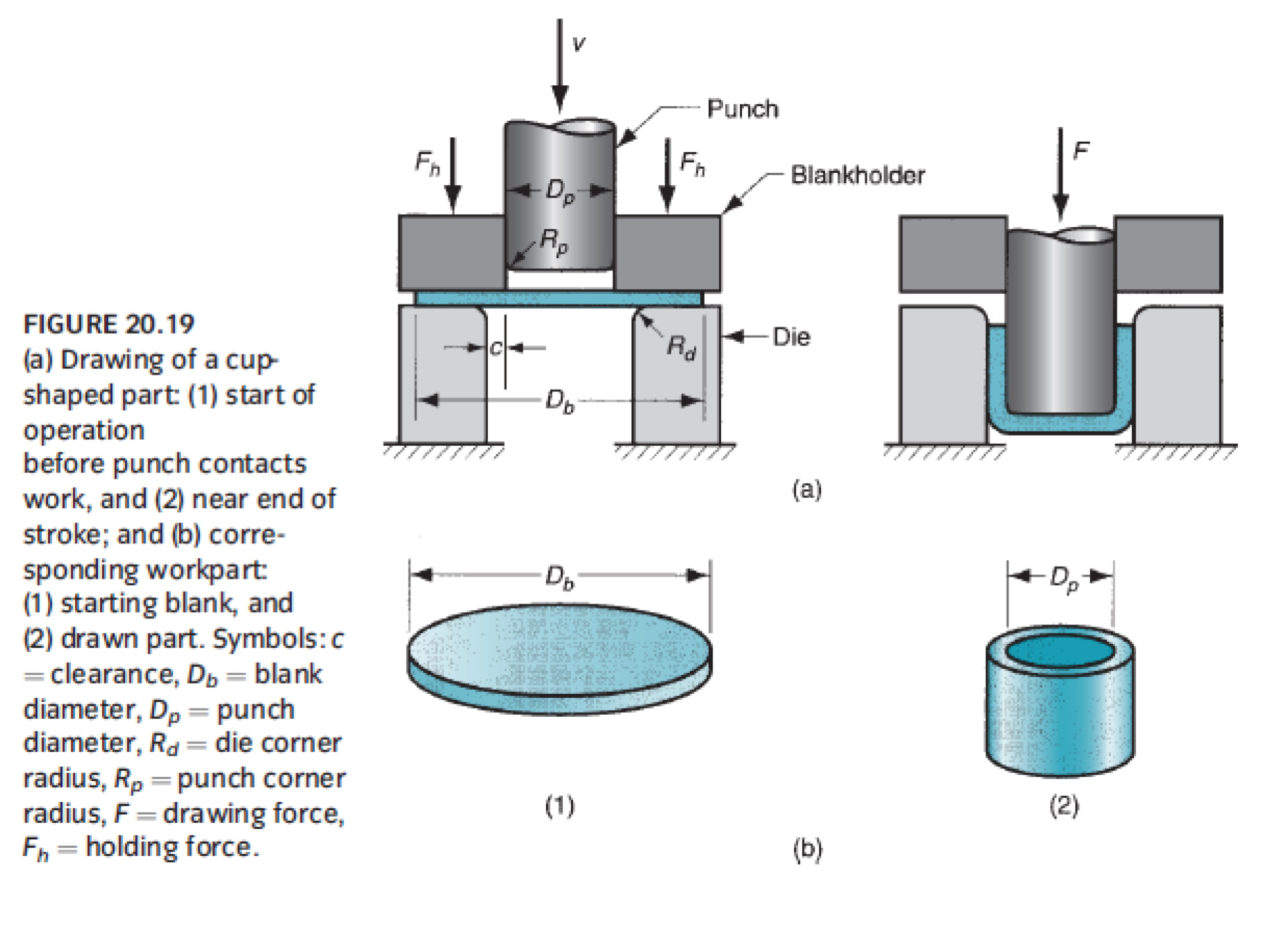

Web the primary function of a die is to give form to sheet metal in the drawing process. Web metal drawing is a metalworking process where a workpiece is pulled through a die to reduce its diameter and increase its length. The dust or other scale particle should clean from the rod. Web figure:291 the process deep drawing of sheet metal is performed with a punch and die. Web drawing can be defined as a forming process in which the flow of metal into a cavity or over a post is controlled. The process of drawing metal wires, rods, and bars is a crucial technique in the manufacturing industry. Web metalworking is the process of shaping a metal into a part or component.

Metal Forming Basic, Types , Diagram , Classification Learn

Products like paper clips and helical springs are manufactured using the metal drawing process. The mold for deep drawing is been called deep drawing die. Small diameter rods and tubes are also. This process is.

32 Basic sheet metalworking operations (a) bending, (b) drawing and

The die cavity matches the punch and is a little wider to allow for its passage, as well as clearance. Web drawing is a metal forming process in which a product is made by controlling.

Metal Drawing How Metal Drawing Works

Shearing is a cutting process used to cut sheet metal along a straight line. What are the different types of dies? Types of deep drawing parts As such, the quality of a die directly impacts.

Metal Drawing

Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under.

The Last Guide to Sheet Metal Forming You Will Ever Need

The dust or other scale particle should clean from the rod. It is an essential aspect of manufacturing in various industries, such as automotive, aerospace, construction, and consumer products. Drawing is a metalworking technique classified.

Sheet Metal Drawing Process Bornmodernbaby

In the corners of a draw and anywhere there is a radial profile, the metal is in compression. The metal drawing process in manufacturing industry is usually performed cold. Web screws, bonding, riveting, and welding.

Deep drawing of sheet metal

The surface of the bar or tube is coated with a drawing lubricant such as phosphate or oil to aid cold. Web deep drawing is a processing method that uses a drawing die to press.

Basics of Sheet Metal Design Consumer Hardware Guide Hardware FYI

Web first a hot rolled rod is created by other metal forming processes like forging, extruding, centrifugal casting etc. Web deep drawing allows for the creation of complex hollow shapes with consistent wall thickness and.

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

The dust or other scale particle should clean from the rod. Web first a hot rolled rod is created by other metal forming processes like forging, extruding, centrifugal casting etc. This setup is similar to.

Metal Drawing

Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under.

Metal Drawing Process Drawing is a metalworking technique classified under forming, or the deformation of a material by the application of forces to the desired shape without the addition or removal of any of the material. The dust or other scale particle should clean from the rod. Web deep drawing allows for the creation of complex hollow shapes with consistent wall thickness and precise dimensions. Web metal drawing metal drawing process. Web figure 1 ears are the result of varying metal flow patterns that occur during the drawing process.