Intro

Optimize inventory with the Min Max Formula, a strategic approach to manage stock levels, reduce waste, and improve supply chain efficiency, using minimum and maximum thresholds, reorder points, and economic order quantities.

Effective inventory management is crucial for businesses to ensure they have enough stock to meet customer demand without overstocking, which can lead to waste and unnecessary costs. One of the key strategies in inventory management is the use of the Min-Max formula. This formula helps businesses determine the optimal inventory levels by setting a minimum and maximum quantity for each product. In this article, we will delve into the world of inventory management, exploring the importance of the Min-Max formula, how it works, and its benefits for businesses.

The Min-Max formula is a simple yet effective tool that helps businesses manage their inventory levels. It involves setting two key quantities for each product: the minimum quantity and the maximum quantity. The minimum quantity is the lowest amount of stock that a business wants to hold, while the maximum quantity is the highest amount of stock that a business is willing to hold. By setting these two quantities, businesses can ensure that they have enough stock to meet customer demand without overstocking.

Understanding the Min-Max Formula

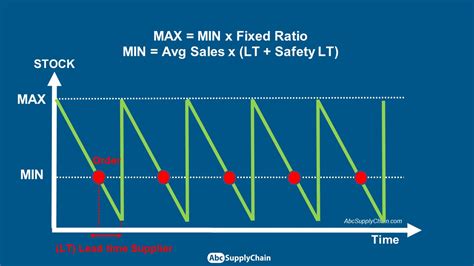

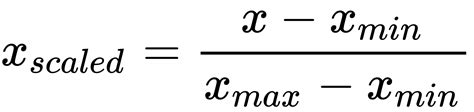

The Min-Max formula is calculated using the following formula: Min = (Demand x Lead Time) + Safety Stock, and Max = Min + (Demand x Reorder Cycle Time). The demand refers to the average amount of stock sold per unit of time, the lead time is the time it takes for new stock to arrive, the safety stock is the extra stock held to account for uncertainties, and the reorder cycle time is the time between orders.

Key Components of the Min-Max Formula

The Min-Max formula involves several key components, including demand, lead time, safety stock, and reorder cycle time. Understanding these components is crucial for effective inventory management. Demand refers to the average amount of stock sold per unit of time, and it is usually calculated using historical sales data. Lead time refers to the time it takes for new stock to arrive, and it can vary depending on the supplier and the shipping method.Benefits of the Min-Max Formula

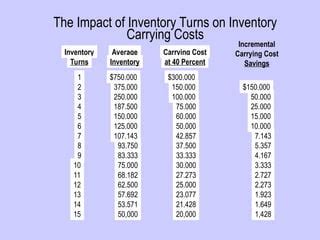

The Min-Max formula offers several benefits for businesses, including reduced inventory costs, improved customer service, and increased efficiency. By setting optimal inventory levels, businesses can reduce the risk of overstocking and understocking, which can lead to waste and lost sales. The Min-Max formula also helps businesses to improve their customer service by ensuring that they have enough stock to meet customer demand.

Implementing the Min-Max Formula

Implementing the Min-Max formula involves several steps, including calculating the minimum and maximum quantities, setting reorder points, and monitoring inventory levels. Calculating the minimum and maximum quantities involves using the Min-Max formula, while setting reorder points involves determining when to order new stock. Monitoring inventory levels involves tracking the amount of stock on hand and adjusting the minimum and maximum quantities as needed.Common Challenges in Inventory Management

Despite the benefits of the Min-Max formula, inventory management can be challenging, especially for small businesses or businesses with complex supply chains. Common challenges include inaccurate demand forecasting, lead time variability, and stockouts. Inaccurate demand forecasting can lead to overstocking or understocking, while lead time variability can make it difficult to predict when new stock will arrive. Stockouts can lead to lost sales and damaged customer relationships.

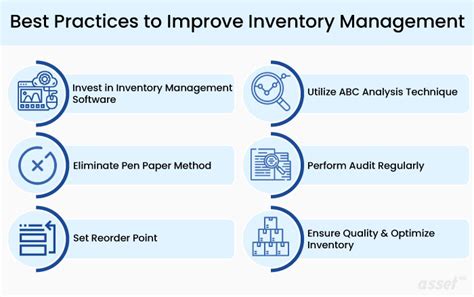

Best Practices in Inventory Management

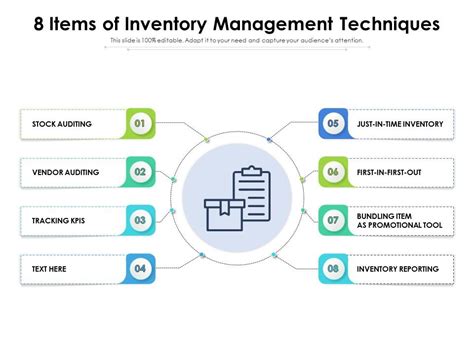

Best practices in inventory management include regularly reviewing and adjusting inventory levels, using inventory management software, and implementing a just-in-time (JIT) inventory system. Regularly reviewing and adjusting inventory levels involves tracking inventory levels and adjusting the minimum and maximum quantities as needed. Using inventory management software involves using specialized software to track inventory levels and automate inventory management tasks. Implementing a JIT inventory system involves ordering and receiving inventory just in time to meet customer demand.Inventory Management Software

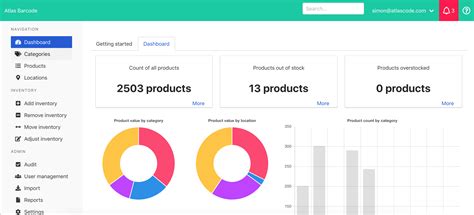

Inventory management software is a crucial tool for businesses, especially those with complex supply chains or large inventories. This software helps businesses to track inventory levels, automate inventory management tasks, and optimize inventory levels. Common features of inventory management software include inventory tracking, automated reporting, and demand forecasting.

Features of Inventory Management Software

Features of inventory management software include inventory tracking, automated reporting, and demand forecasting. Inventory tracking involves tracking the amount of stock on hand, while automated reporting involves generating reports on inventory levels and inventory management metrics. Demand forecasting involves using historical sales data and other factors to predict future demand.Just-in-Time (JIT) Inventory System

A JIT inventory system is a strategy that involves ordering and receiving inventory just in time to meet customer demand. This strategy helps businesses to reduce inventory costs and improve customer service. The JIT inventory system involves several key components, including demand forecasting, lead time reduction, and supplier partnerships.

Benefits of a JIT Inventory System

The benefits of a JIT inventory system include reduced inventory costs, improved customer service, and increased efficiency. Reduced inventory costs involve reducing the amount of inventory on hand, while improved customer service involves ensuring that customers receive their products on time. Increased efficiency involves streamlining inventory management processes and reducing waste.Inventory Management Image Gallery

What is the Min-Max formula?

+The Min-Max formula is a simple yet effective tool that helps businesses manage their inventory levels by setting a minimum and maximum quantity for each product.

What are the benefits of the Min-Max formula?

+The benefits of the Min-Max formula include reduced inventory costs, improved customer service, and increased efficiency.

How do I implement the Min-Max formula?

+Implementing the Min-Max formula involves calculating the minimum and maximum quantities, setting reorder points, and monitoring inventory levels.

What is inventory management software?

+Inventory management software is a crucial tool for businesses that helps to track inventory levels, automate inventory management tasks, and optimize inventory levels.

What is a JIT inventory system?

+A JIT inventory system is a strategy that involves ordering and receiving inventory just in time to meet customer demand, helping businesses to reduce inventory costs and improve customer service.

In conclusion, the Min-Max formula is a powerful tool for businesses to manage their inventory levels effectively. By setting optimal inventory levels, businesses can reduce inventory costs, improve customer service, and increase efficiency. The Min-Max formula involves calculating the minimum and maximum quantities, setting reorder points, and monitoring inventory levels. Inventory management software and JIT inventory systems are also crucial tools for businesses to optimize their inventory levels and improve their overall performance. We hope this article has provided you with valuable insights into the world of inventory management and the Min-Max formula. If you have any questions or comments, please do not hesitate to reach out to us. Share this article with your friends and colleagues to help them improve their inventory management skills.