Intro

Calculate process capability with 5 ways to compute Cpk in Excel, including statistical methods, data analysis, and quality control metrics for precision and accuracy.

In today's data-driven world, understanding and analyzing process capability is crucial for maintaining high standards of quality in manufacturing and other fields. One key metric used to assess process capability is Cpk, which stands for Capability Index. It measures how closely a process is able to produce output within specified limits. Excel, being a versatile and widely used tool for data analysis, can be employed to compute Cpk. Here's how you can do it in five different ways, each tailored to different scenarios or preferences.

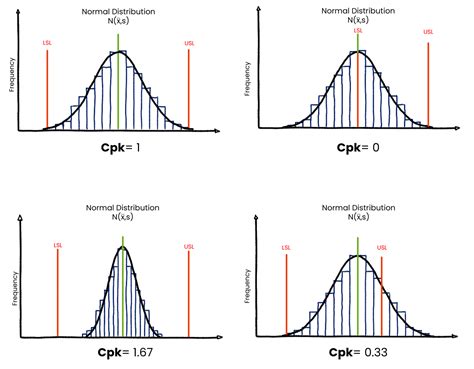

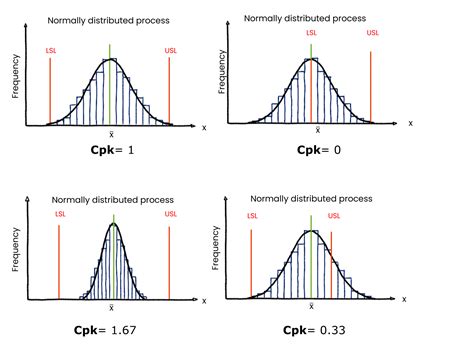

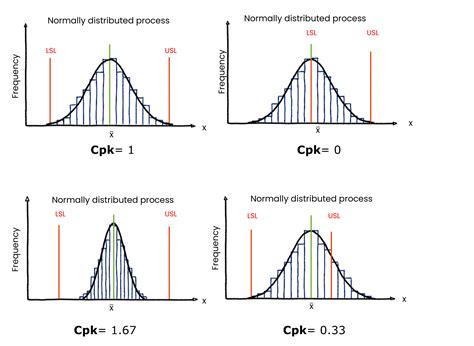

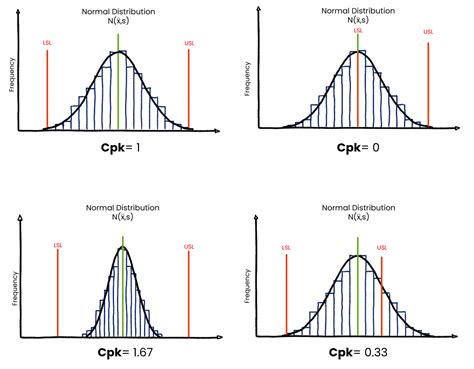

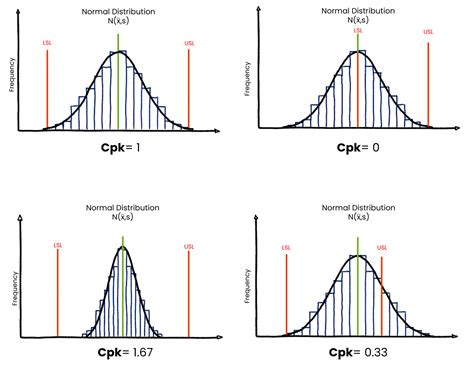

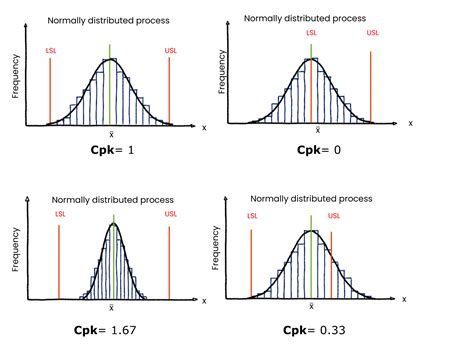

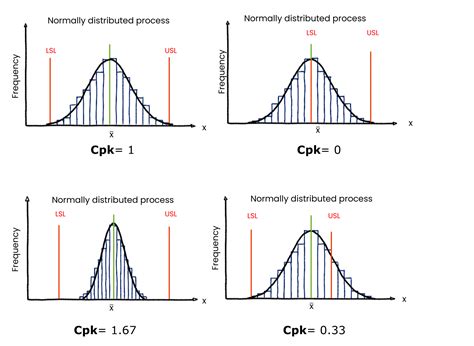

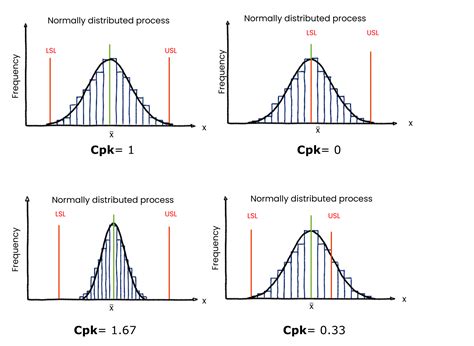

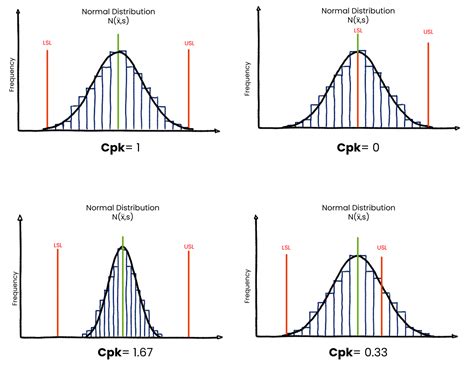

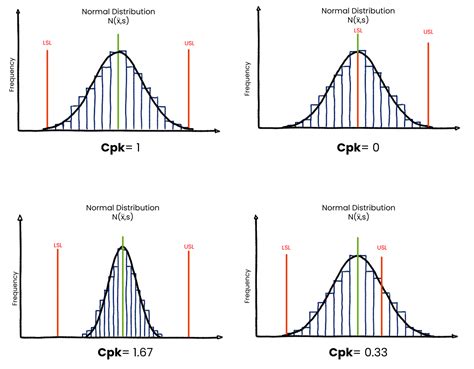

First, let's understand the basics. The Cpk formula is given by Cpk = min(CPU, CPL), where CPU (Capability Index Upper) and CPL (Capability Index Lower) are calculated as follows: CPU = (USL - Mean) / (3 * Standard Deviation) and CPL = (Mean - LSL) / (3 * Standard Deviation), with USL being the Upper Specification Limit, LSL the Lower Specification Limit, and Mean and Standard Deviation being the process mean and standard deviation, respectively.

Understanding Cpk and Its Importance

Cpk is a critical measure because it not only tells us if a process is capable of producing within specifications but also indicates how centered the process is. A higher Cpk value indicates a more capable process. The minimum acceptable Cpk value often cited is 1.33, which corresponds to a process that is well-centered and has a very low defect rate.

Method 1: Manual Calculation in Excel

For those who prefer a straightforward approach or are dealing with a small dataset, manual calculation is feasible. You calculate the mean and standard deviation of your dataset, then apply the Cpk formula directly. Excel functions like AVERAGE() for mean and STDEV.S() for standard deviation (assuming you're using a sample of the population) are useful here.

- Calculate the mean of your dataset using

=AVERAGE(range). - Calculate the standard deviation using

=STDEV.S(range). - Input your USL and LSL.

- Calculate CPU and CPL using the respective formulas.

- Determine Cpk as the minimum of CPU and CPL.

Method 2: Using Excel Formulas for Direct Calculation

If you prefer a more streamlined approach, you can calculate Cpk directly within Excel using formulas without needing to break down the calculation into separate steps for mean, standard deviation, CPU, and CPL.

- Assume your data is in column A, USL in cell B1, and LSL in cell B2.

- Use the formula for Cpk, incorporating the calculations for mean, standard deviation, CPU, and CPL into a single formula or use separate cells for intermediate calculations for clarity.

Example: =MIN((B1-AVERAGE(A:A)-3*STDEV.S(A:A)), (AVERAGE(A:A)-B2-3*STDEV.S(A:A))) adjusted to correctly reflect the Cpk formula.

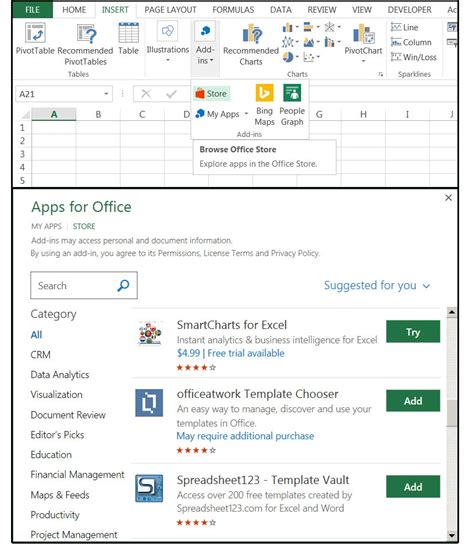

Method 3: Utilizing Excel Add-ins for Statistical Analysis

For those who frequently perform statistical analysis, Excel add-ins like Analysis ToolPak (ATP) can be incredibly useful. While ATP doesn't directly calculate Cpk, it provides functions for mean and standard deviation, which can then be used in Cpk calculations.

- Ensure Analysis ToolPak is installed and enabled in Excel.

- Use ATP's functions for descriptive statistics to find mean and standard deviation.

- Apply these values to calculate Cpk manually or through a formula.

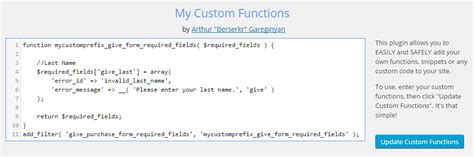

Method 4: Creating a Custom Excel Function (User-Defined Function)

For advanced users, creating a custom function (User-Defined Function, UDF) in VBA (Visual Basic for Applications) can streamline the process, especially when dealing with multiple datasets.

- Open the Visual Basic Editor in Excel.

- Insert a new module.

- Write a VBA function that calculates Cpk based on input parameters (data range, USL, LSL).

- Save the workbook as an Excel Macro-Enabled Workbook (.xlsm).

Example VBA code snippet:

Function CalculateCpk(dataRange As Range, usl As Double, lsl As Double) As Double

Dim mean As Double

Dim stdDev As Double

mean = Application.WorksheetFunction.Average(dataRange)

stdDev = Application.WorksheetFunction.StDev_S(dataRange)

Dim cpu As Double

Dim cpl As Double

cpu = (usl - mean) / (3 * stdDev)

cpl = (mean - lsl) / (3 * stdDev)

CalculateCpk = Application.WorksheetFunction.Min(cpu, cpl)

End Function

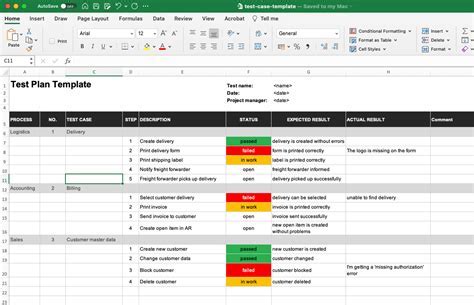

Method 5: Using Excel Templates for Process Capability Analysis

For a more structured approach, especially in industries where process capability analysis is routine, using pre-designed Excel templates can be beneficial. These templates often include built-in formulas and charts for Cpk calculation, making the process more efficient.

- Search for and download a suitable Excel template for process capability analysis.

- Input your data, USL, and LSL into the designated areas.

- The template will calculate Cpk and possibly display it in a graphical format for easier interpretation.

Gallery of Cpk Calculation Examples

Cpk Calculation Examples

What is Cpk, and why is it important in quality control?

+Cpk, or Capability Index, is a measure of a process's ability to produce output within specified limits. It's crucial for ensuring high-quality products and reducing defects.

How do I calculate Cpk in Excel?

+You can calculate Cpk in Excel by using formulas for mean and standard deviation, then applying the Cpk formula. Alternatively, you can use Excel add-ins, create a custom function, or utilize pre-designed templates.

What is the minimum acceptable Cpk value?

+The minimum acceptable Cpk value often cited is 1.33, indicating a process that is well-centered and has a very low defect rate.

In conclusion, calculating Cpk in Excel can be approached in various ways, each with its own advantages. Whether you prefer a straightforward manual calculation, the efficiency of formulas, the power of add-ins, the customization of VBA, or the simplicity of templates, Excel provides a versatile platform for process capability analysis. By understanding and applying these methods, professionals can better assess and improve their processes, leading to higher quality products and enhanced customer satisfaction. We invite you to share your experiences with Cpk calculations and Excel, and to explore more topics related to quality control and statistical analysis.