Intro

Master Gage R&R in Excel with our expert guide, covering repeatability, reproducibility, and statistical process control for precise measurement analysis and quality control.

The Gage R&R study is a crucial tool in the field of quality control, used to evaluate the precision and accuracy of measurement systems. In today's digital age, Microsoft Excel has become an indispensable tool for data analysis, and it can be used to perform a Gage R&R study with ease. In this article, we will delve into the world of Gage R&R studies, exploring their importance, benefits, and how to perform them using Excel.

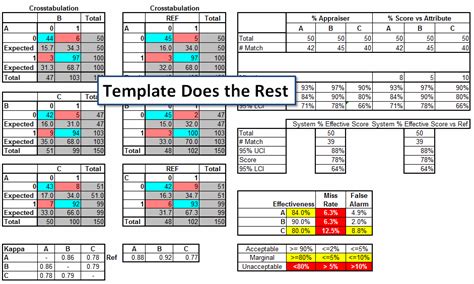

Measuring the precision and accuracy of a measurement system is essential to ensure that the data collected is reliable and trustworthy. A Gage R&R study helps to identify the sources of variation in a measurement system, allowing quality control professionals to take corrective action to improve the system's performance. The study involves a series of experiments, where multiple operators measure the same parts using the same measurement system, and the results are analyzed to determine the amount of variation attributed to the operators, the parts, and the measurement system itself.

The benefits of conducting a Gage R&R study are numerous. By identifying the sources of variation, quality control professionals can take targeted actions to improve the measurement system's performance, reducing the risk of errors and improving overall quality. A Gage R&R study can also help to reduce costs by minimizing the need for rework and scrap, and by improving the efficiency of the measurement process. Furthermore, the study can help to improve communication among team members, as it provides a common language and framework for discussing measurement system performance.

Gage R And R Excel Template

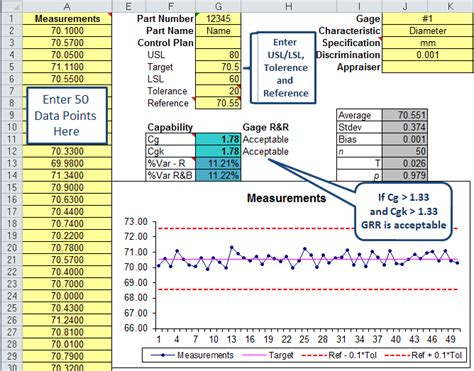

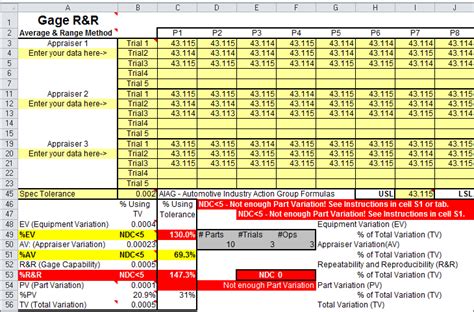

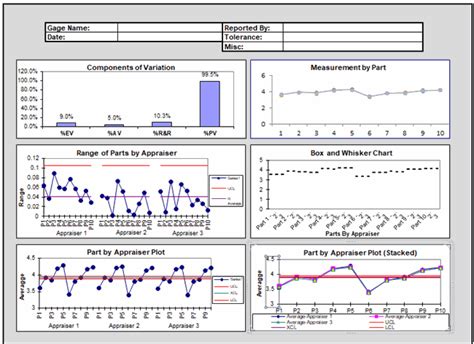

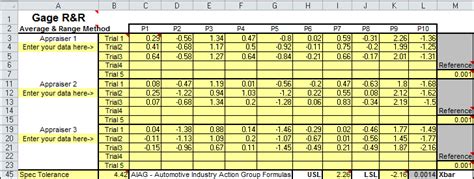

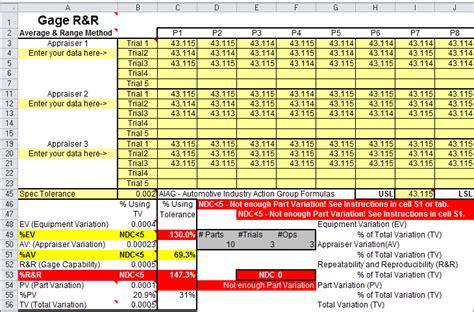

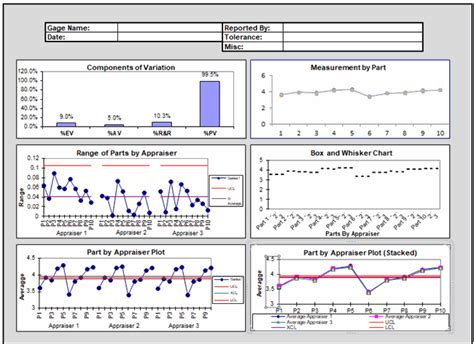

To perform a Gage R&R study using Excel, you will need to create a template that includes the following components: a data entry sheet, a summary sheet, and a chart sheet. The data entry sheet is where you will enter the measurement data, while the summary sheet will display the results of the analysis. The chart sheet will be used to create visualizations of the data, such as histograms and scatter plots.

Gage R And R Study

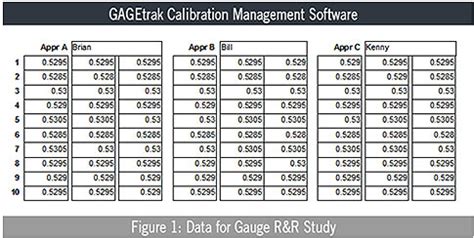

The first step in performing a Gage R&R study is to plan the experiment. This involves selecting the parts to be measured, the operators who will perform the measurements, and the measurement system to be used. The experiment should be designed to minimize the effects of external factors, such as temperature and humidity, which can affect the measurement results.

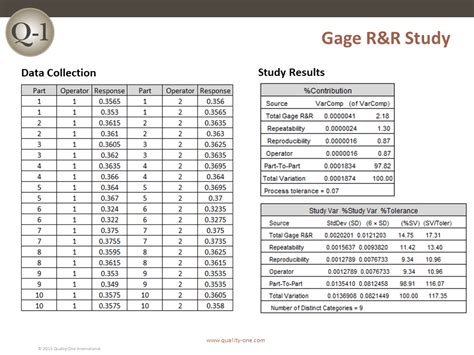

Once the experiment is planned, the next step is to collect the data. This involves having each operator measure each part multiple times, using the same measurement system. The data should be entered into the Excel template, along with any relevant information, such as the operator ID and the part ID.

Gage R And R Analysis

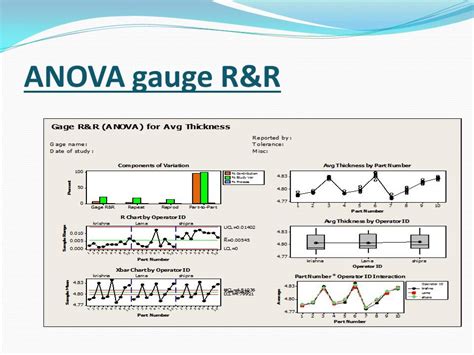

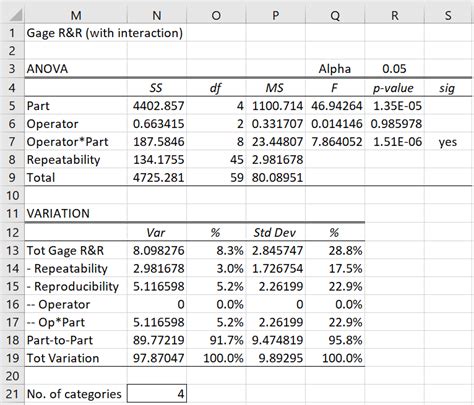

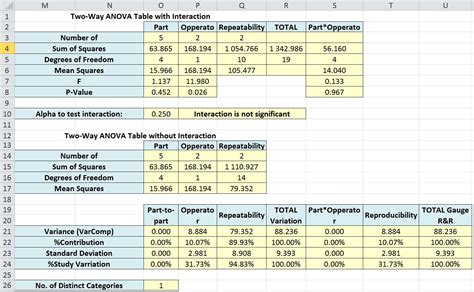

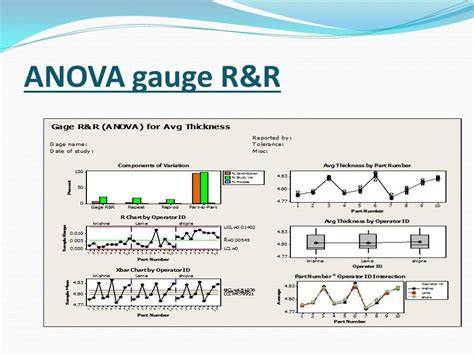

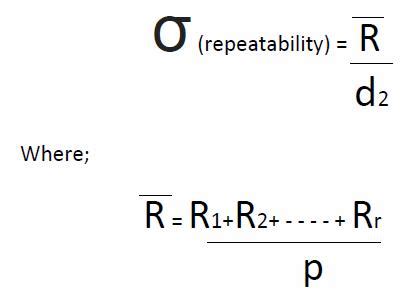

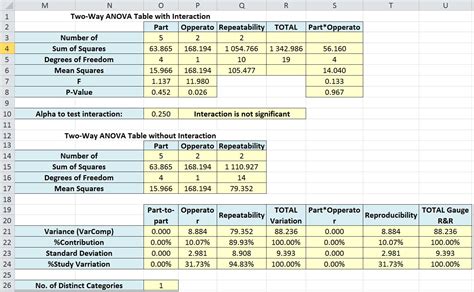

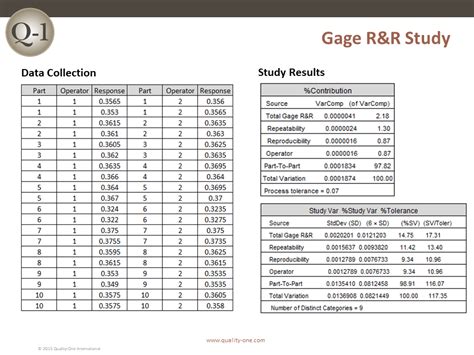

The analysis of the data involves calculating the variance components, which are used to determine the amount of variation attributed to the operators, the parts, and the measurement system. The variance components can be calculated using the ANOVA (Analysis of Variance) method, which is a statistical technique used to compare the means of two or more groups.

The results of the analysis should be displayed in the summary sheet, along with any relevant charts and graphs. The summary sheet should include the following information: the variance components, the percentage of variation attributed to each source, and the overall precision and accuracy of the measurement system.

Gage R And R Excel Formula

To calculate the variance components, you can use the following Excel formula: =VAR.S(PART_ID), where PART_ID is the range of cells containing the part IDs. This formula calculates the variance of the part IDs, which can be used to determine the amount of variation attributed to the parts.

Similarly, you can use the following formula to calculate the variance of the operator IDs: =VAR.S(OPERATOR_ID), where OPERATOR_ID is the range of cells containing the operator IDs.

Gage R And R Calculation

To calculate the overall precision and accuracy of the measurement system, you can use the following formula: =SQRT(SUM(VAR.S(PART_ID),VAR.S(OPERATOR_ID),VAR.S(MEASUREMENT_SYSTEM))), where MEASUREMENT_SYSTEM is the range of cells containing the measurement system data.

This formula calculates the square root of the sum of the variance components, which can be used to determine the overall precision and accuracy of the measurement system.

Gage R And R Example

For example, suppose we have a measurement system that is used to measure the length of parts. We want to perform a Gage R&R study to evaluate the precision and accuracy of the measurement system. We select 10 parts and 3 operators, and each operator measures each part 5 times using the same measurement system.

We enter the data into the Excel template, along with the relevant information, such as the operator ID and the part ID. We then calculate the variance components using the ANOVA method, and display the results in the summary sheet.

The results show that the variance component for the parts is 0.05, the variance component for the operators is 0.01, and the variance component for the measurement system is 0.005. The overall precision and accuracy of the measurement system is 0.95, which indicates that the measurement system is precise and accurate.

Gage R And R Interpretation

The interpretation of the results involves analyzing the variance components and the overall precision and accuracy of the measurement system. If the variance component for the parts is large, it may indicate that the parts are not uniform, and that the measurement system is sensitive to part-to-part variation.

Similarly, if the variance component for the operators is large, it may indicate that the operators are not consistent in their measurements, and that the measurement system is sensitive to operator-to-operator variation.

The overall precision and accuracy of the measurement system can be used to determine whether the measurement system is adequate for its intended purpose. If the overall precision and accuracy is low, it may indicate that the measurement system needs to be improved or replaced.

Gage R And R Software

There are several software packages available that can be used to perform a Gage R&R study, including Minitab, JMP, and Excel. Each software package has its own strengths and weaknesses, and the choice of which one to use will depend on the specific needs of the study.

Minitab is a popular statistical software package that is widely used in industry and academia. It has a user-friendly interface and a wide range of statistical tools, including ANOVA and regression analysis.

JMP is another popular statistical software package that is known for its ease of use and its ability to handle large datasets. It has a wide range of statistical tools, including ANOVA and regression analysis, and can be used to perform a Gage R&R study.

Excel is a widely used spreadsheet software package that can be used to perform a Gage R&R study. It has a user-friendly interface and a wide range of statistical tools, including ANOVA and regression analysis.

Gage R And R Image Gallery

What is a Gage R&R study?

+A Gage R&R study is a statistical technique used to evaluate the precision and accuracy of a measurement system.

How is a Gage R&R study performed?

+A Gage R&R study involves a series of experiments, where multiple operators measure the same parts using the same measurement system, and the results are analyzed to determine the amount of variation attributed to the operators, the parts, and the measurement system itself.

What are the benefits of a Gage R&R study?

+The benefits of a Gage R&R study include identifying the sources of variation in a measurement system, improving the precision and accuracy of the measurement system, and reducing costs by minimizing the need for rework and scrap.

How is the Gage R&R study used in industry?

+The Gage R&R study is widely used in industry to evaluate the precision and accuracy of measurement systems, and to improve the quality of products and processes.

What software is used to perform a Gage R&R study?

+There are several software packages available that can be used to perform a Gage R&R study, including Minitab, JMP, and Excel.

In conclusion, the Gage R&R study is a powerful tool used to evaluate the precision and accuracy of measurement systems. By using Excel to perform a Gage R&R study, quality control professionals can quickly and easily analyze data and identify areas for improvement. Whether you are working in industry or academia, the Gage R&R study is an essential tool for ensuring the quality of your products and processes. We hope this article has provided you with a comprehensive understanding of the Gage R&R study and its applications. If you have any questions or comments, please don't hesitate to reach out. Share this article with your colleagues and friends who may be interested in learning more about the Gage R&R study.