Intro

Streamline processes with our Value Stream Mapping Excel Template, utilizing lean principles and workflow analysis to optimize efficiency, reduce waste, and improve productivity in your business operations and supply chain management.

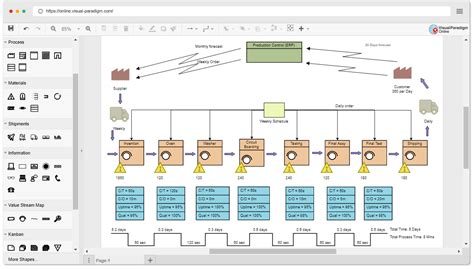

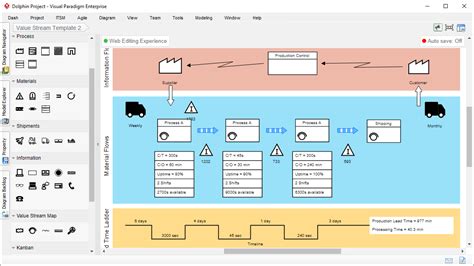

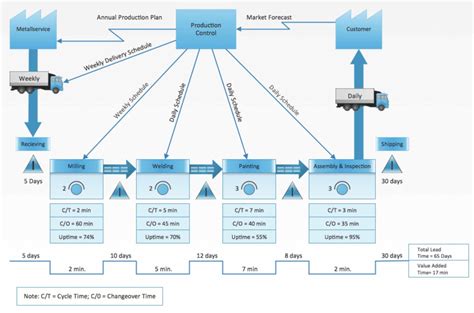

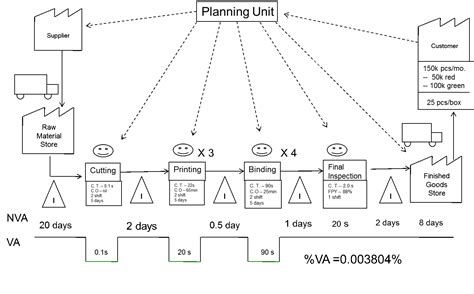

The importance of efficient processes in any organization cannot be overstated. One tool that has gained popularity in recent years to achieve this efficiency is Value Stream Mapping (VSM). VSM is a method used to analyze and improve the flow of processes within an organization, focusing on reducing waste and maximizing value-added activities. For those looking to implement VSM, utilizing a Value Stream Mapping Excel template can be a highly effective approach. This article will delve into the world of VSM, its benefits, how to create or use a VSM Excel template, and provide insights into its application across various industries.

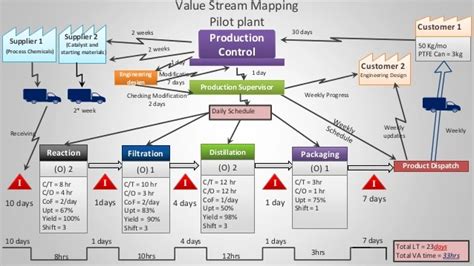

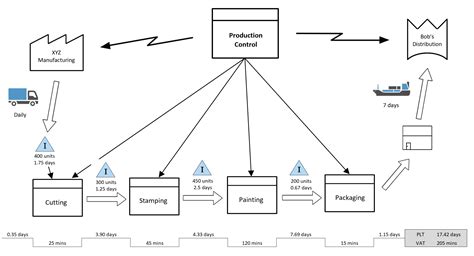

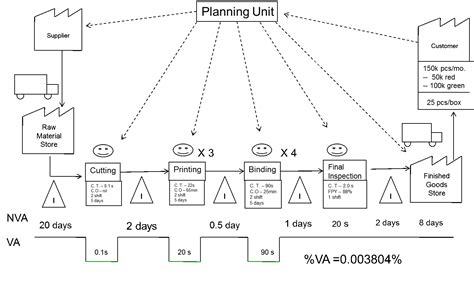

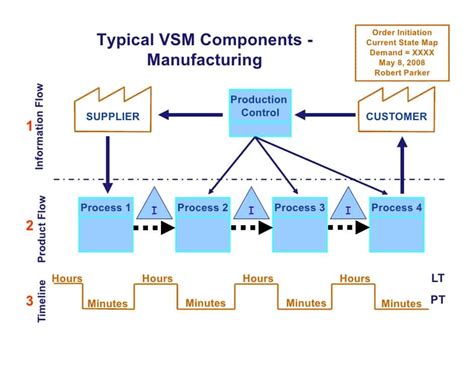

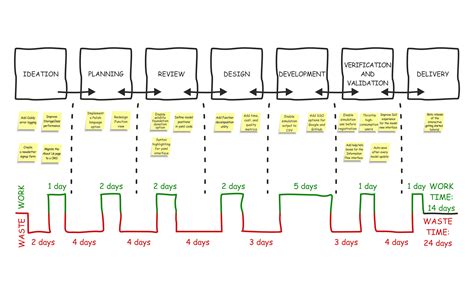

Value Stream Mapping is essentially a visual representation of all the processes involved in creating a product or delivering a service, from start to finish. It helps in identifying areas of waste and inefficiency, allowing organizations to streamline their processes and improve productivity. The methodology originated in the manufacturing sector, particularly in the Toyota Production System, but its application has since expanded to service industries and software development.

Implementing VSM involves several key steps, including identifying the value stream, mapping the current state, envisioning the future state, and implementing the future state. The current state map reflects how the process currently operates, highlighting both value-added and non-value-added activities. The future state map, on the other hand, represents an ideal process with minimized waste and optimized efficiency.

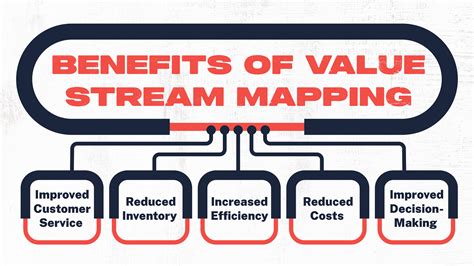

Benefits of Value Stream Mapping

The benefits of VSM are multifaceted. It leads to reduced lead times, lower costs, and improved quality by eliminating unnecessary steps and focusing on continuous improvement. Moreover, VSM enhances collaboration among team members by providing a shared understanding of the process and its goals. It also aids in prioritizing improvements based on their potential impact on the value stream.

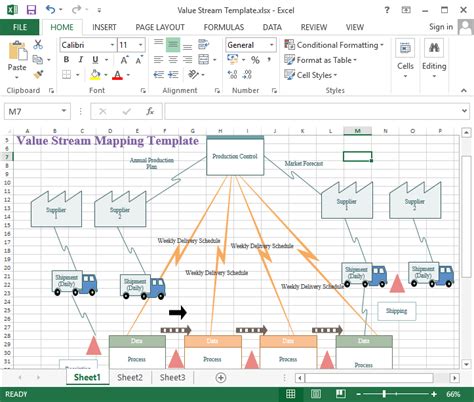

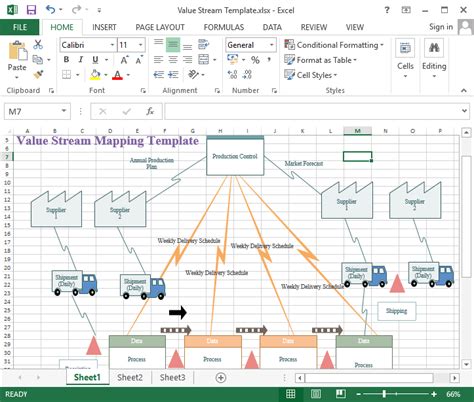

Creating a Value Stream Mapping Excel Template

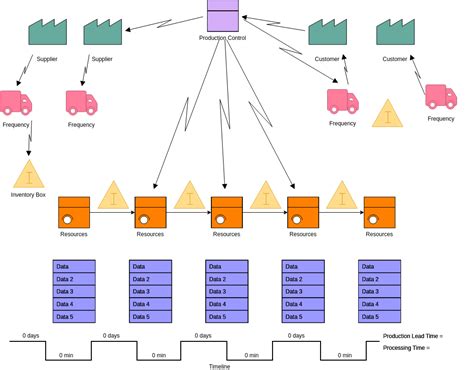

For organizations looking to adopt VSM, creating or using a Value Stream Mapping Excel template can be a practical first step. An Excel template for VSM typically includes worksheets for mapping the current and future states of the process, calculating lead times and process times, and identifying areas for improvement.

To create a basic VSM template in Excel, you would start by setting up a spreadsheet that can accommodate the flow of your process. This might include columns for process steps, process time, lead time, and notes on whether the step adds value. Additional sheets can be used for data analysis, such as calculating total lead time and identifying bottlenecks.

Steps to Use a VSM Excel Template

- Identify the Value Stream: Determine the specific process or product family you want to map.

- Gather Data: Collect data on each process step, including process time, lead time, and whether the step is value-added.

- Map the Current State: Use the template to create a visual representation of the current process, highlighting inefficiencies and areas for improvement.

- Envision the Future State: Based on your analysis, design an ideal future state that minimizes waste and maximizes efficiency.

- Implement the Future State: Use your future state map as a guide to implement changes and continuously monitor and improve the process.

Applications Across Industries

While VSM originated in manufacturing, its principles can be applied to any process, making it versatile across various industries. In software development, VSM can help streamline the development lifecycle, reducing time to market and improving product quality. In healthcare, it can be used to improve patient flow and reduce wait times. In services, VSM can enhance customer experience by eliminating unnecessary steps and focusing on value-added interactions.

Industry Examples

- Manufacturing: A company producing automotive parts used VSM to reduce production lead time by 30% and improve quality ratings.

- Software Development: A tech firm applied VSM to its development process, resulting in a 25% reduction in time to market for new features.

- Healthcare: A hospital utilized VSM to streamline patient intake, reducing wait times by 40% and improving patient satisfaction scores.

Best Practices for Implementing VSM

Successful implementation of VSM requires careful planning, strong leadership support, and a culture of continuous improvement. It's essential to engage all stakeholders in the process, ensure that the mapping is data-driven, and to prioritize improvements based on their impact on the value stream.

Key Considerations

- Engage Stakeholders: Involve team members from all levels in the VSM process to ensure a comprehensive understanding and buy-in.

- Data-Driven Decisions: Use data to identify areas for improvement and to measure the effectiveness of changes.

- Continuous Improvement: View VSM as an ongoing process, regularly reviewing and updating maps to reflect changes and improvements.

Value Stream Mapping Image Gallery

What is Value Stream Mapping?

+Value Stream Mapping is a visual method for analyzing and improving the flow of processes within an organization, focusing on reducing waste and maximizing value-added activities.

How does Value Stream Mapping benefit an organization?

+VSM benefits an organization by reducing lead times, lowering costs, and improving quality. It also enhances collaboration and aids in prioritizing improvements based on their potential impact.

Can Value Stream Mapping be applied across different industries?

+Yes, VSM can be applied across various industries, including manufacturing, software development, healthcare, and services, to improve process efficiency and customer satisfaction.

In conclusion, Value Stream Mapping is a powerful tool for organizations seeking to improve their processes, reduce waste, and enhance customer satisfaction. By utilizing a Value Stream Mapping Excel template, businesses can systematically analyze and improve their value streams, leading to significant improvements in efficiency, quality, and profitability. Whether you're in manufacturing, services, or any other industry, embracing the principles of VSM can be a pivotal step towards achieving operational excellence. We invite you to share your experiences with VSM, ask questions, or explore how you can start implementing these principles in your organization today.